By David Ponce

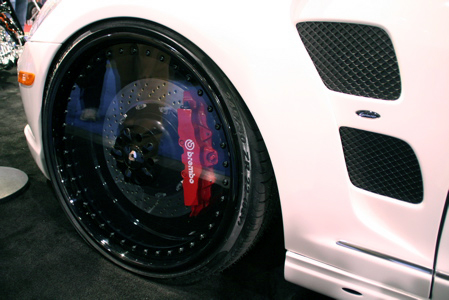

Doug McGoon (we love the name) has invented what may be the slickest set of wheels we’ve ever laid our eyes on: clear rims, made from a thick slab of polycarbonate. Now manufactured by D’Vinci Forgiato the wheels are made by

a technique known as bezel setting which only master diamond setters can know, where the diamonds are just slightly larger than the bezel they are set into and are held in place by pressure. Understanding this, we put the same care and consideration towards the Radurra as we would towards a fine watch. By eliminating the alloy center of a three piece forged wheel and setting into its place a hard coated polycarbonate center with a glass-like finish we achieve an amazing and stunning look, with a finished product that looks too good to be a wheel.

We agree, it looks too good to be a wheel, and costs too much to be bought, at least by us. At $5,000 per wheel, they’re mainly showpieces, though the video we link to shows a 350Z with the Radurras on, doing some rubber burning. We imagine people will talk about stress resistance, heat resistance and whatnot, though the company claim they’ve been “SAE tested, certified and passed Impact, cornering and radial tests.”

They were on display a month ago at the SEMA show, and are apparently available for purchase. A custom order takes 6 to 8 weeks to deliver. Keep reading for a bunch more pictures, and links to a video, product page and all that jive.

[ Video: Radurras In Action ]

[ Forgiato Radurra Product Page ] VIA [Slashgear ]

Fascinating idea, I like these much better than those annoying spinners. They must be hell to keep clean and I hope they come with some sort of protective replaceable cover to ward off dings and scratches.

Wow, better not do any hard braking and come to a quick stop, as in road racing or driver’s ed events. PC , even the bisphenol version used to make bulletproof glass, melts at 250c. Those big red brembos are just getting warmed up at 250C. Also, kiss the clear finish goodbye if gasoline is spilled on them.

Hello, I seem to see you supposed to have invented these rims. Well, odd that I am looking at a patent and copyright contract right now that precedes your date. I thought that you should know this was sent to an invention marketing company and papers were processed for “clear rims” long before yours hit the market.

im very interested in your comment, i happen to know a little bit about this patent you are talking about. what do you know?

To Floyd Rogers let me know asap if you could.

Technical Data

The center is 1.5 or 2? polycarbonate, chemical hard coated both sides.

Weight 20? – 27 lbs, and 22? – 38 lbs (complete wheel weight)

All other parts of the wheel are forged 6061t aluminum

(Inner and outer hoops and Hub center)

SAE tested, certified and passed Impact, cornering and radial tests.

Now in production, average delivery time is 6-8 weeks.

Suggested retail is $5000.00 per wheel

trying to but a set please contact asap

you guy are the best of the best

How can I get a pair for a motorcycle. Not a Crotch Rocket though, a bobber. I'm trying to find a 21″ x 2.185 and an 18″ x 3.5″ rim diameter? Please let me know, thanks.

This is the first time I see this kind of transparent rims. This is an amazing idea. Congrats to the one who created something like this. I design motorcycle saddlebags and I know how it feels when I make a new successful product. Everybody enjoy it and it is for my greatest satisfaction.

This is the first time I see this kind of transparent rims. This is an amazing idea. Congrats to the one who created something like this. I design motorcycle saddlebags and I know how it feels when I make a new successful product. Everybody enjoy it and it is for my greatest satisfaction.

sick as F@#K