By Andrew Liszewski

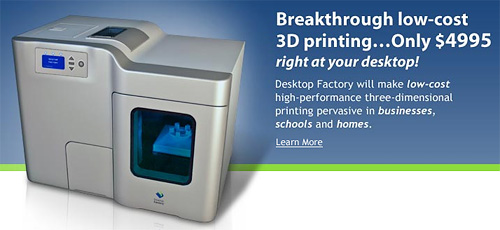

With a price tag of $4,995 we’re not going to be seeing one of these in every home in America anytime soon, but the Desktop Factory proves that the cost of owning your own 3D printer continues to drop. One of the reasons the Desktop Factory is so ‘affordable’ is because it uses an inexpensive halogen light source and plastic powder instead of UV and polymers, which also means the cost of the build material is expected to be about $1 per cubic inch. And the parts can be sanded and painted as soon as they’re finished, without the need for a chemical infiltration curing or strengthening process.

Now given the Desktop Factory is roughly the size of an early laser printer (25x20x20 inches) it will easily fit on any desk, but your 3D creations will be limited to 125ci or roughly 2 liters in volume. So while you won’t be printing out body panels for your home-made Enzo, your bootleg action figure business will be booming.

[ Desktop Factory ] VIA [ The Red Ferret Journal ]

Low cost, desktop 3d printing has been around for a while now if you were willing to 'build-it yourself.

A rep-rap (gotta plug them first, 'cause I'm building one :D) machine can be built for about a fifth of the cost of this thing, and prints in much more durable and inexpensive ABS and HDPE plastics (between five and ten dollars a pound). the rep-rap site also has links to a bunch of 'boot-strap' designs that are cheaper and have vary-ing dificulty curves and capabilities. (reprap.org)

Makerbot has an even cheaper option in their Cupcake CNC machine for $750-950, with similar capabilities but a much smaller volume. Though it also comes as a full kit, whereas rep-rap is just a design and you have to source the parts your self. (makerbot.com)

On the more expensive side of things, Fab@home sells pre-built machines, kits and parts with similar capabilities to the above machines and a decent sized usable volume.

It's still cheaper than the desktop factory though, their most expensive pre-built unit is still only $4100, while cheaper units are available for around $3700, and full kits for $2700

(fabathome.org)

And there are plenty of other options out there, the last year or so has seen a bit of an explosion with regards to desktop rapid-prototyping. No need to wait, the future is now!

Low cost, desktop 3d printing has been around for a while now if you were willing to 'build-it yourself.

A rep-rap (gotta plug them first, 'cause I'm building one :D) machine can be built for about a fifth of the cost of this thing, and prints in much more durable and inexpensive ABS and HDPE plastics (between five and ten dollars a pound). the rep-rap site also has links to a bunch of 'boot-strap' designs that are cheaper and have vary-ing dificulty curves and capabilities. (reprap.org)

Makerbot has an even cheaper option in their Cupcake CNC machine for $750-950, with similar capabilities but a much smaller volume. Though it also comes as a full kit, whereas rep-rap is just a design and you have to source the parts your self. (makerbot.com)

On the more expensive side of things, Fab@home sells pre-built machines, kits and parts with similar capabilities to the above machines and a decent sized usable volume.

It's still cheaper than the desktop factory though, their most expensive pre-built unit is still only $4100, while cheaper units are available for around $3700, and full kits for $2700

(fabathome.org)

And there are plenty of other options out there, the last year or so has seen a bit of an explosion with regards to desktop rapid-prototyping. No need to wait, the future is now!